Introduction to RFID

RFID, or Radio-Frequency Identification, employs electromagnetic fields to identify and track tags attached to objects automatically. These tags contain a microchip and an antenna that transmit data to an RFID reader via radio waves. This technology doesn't require direct line-of-sight for scanning, enabling seamless tracking in various industries.

In tracking, RFID plays a pivotal role across sectors. In logistics, it enables real-time visibility, enhancing inventory management by tracking goods throughout the supply chain. Retailers leverage RFID to monitor merchandise from manufacturing to shelves, reducing stockouts and improving inventory accuracy. Healthcare institutions utilize RFID to track medical equipment, streamline inventory checks, and ensure proper asset utilization.

RFID's versatility extends to access control systems, toll collection, and even pet tracking. Its non-invasive nature and ability to handle large volumes of data swiftly make it an ideal choice for tracking and identifying items efficiently.

Overall, RFID's ability to provide real-time information, enhance accuracy, and streamline tracking processes positions it as an indispensable technology in modern asset management and inventory tracking systems.

Applications of RFID for Asset Tracking

RFID technology finds extensive applications across industries, significantly impacting supply chain management, inventory control, and operational efficiency. Real-world examples illustrate its versatility and effectiveness.

Understanding RFID Asset Tracking Systems

RFID systems, composed of tags, readers, and databases, constitute a cornerstone in modern asset management. Delving deeper into its components and functionalities sheds light on its profound impact:

Components of an RFID System

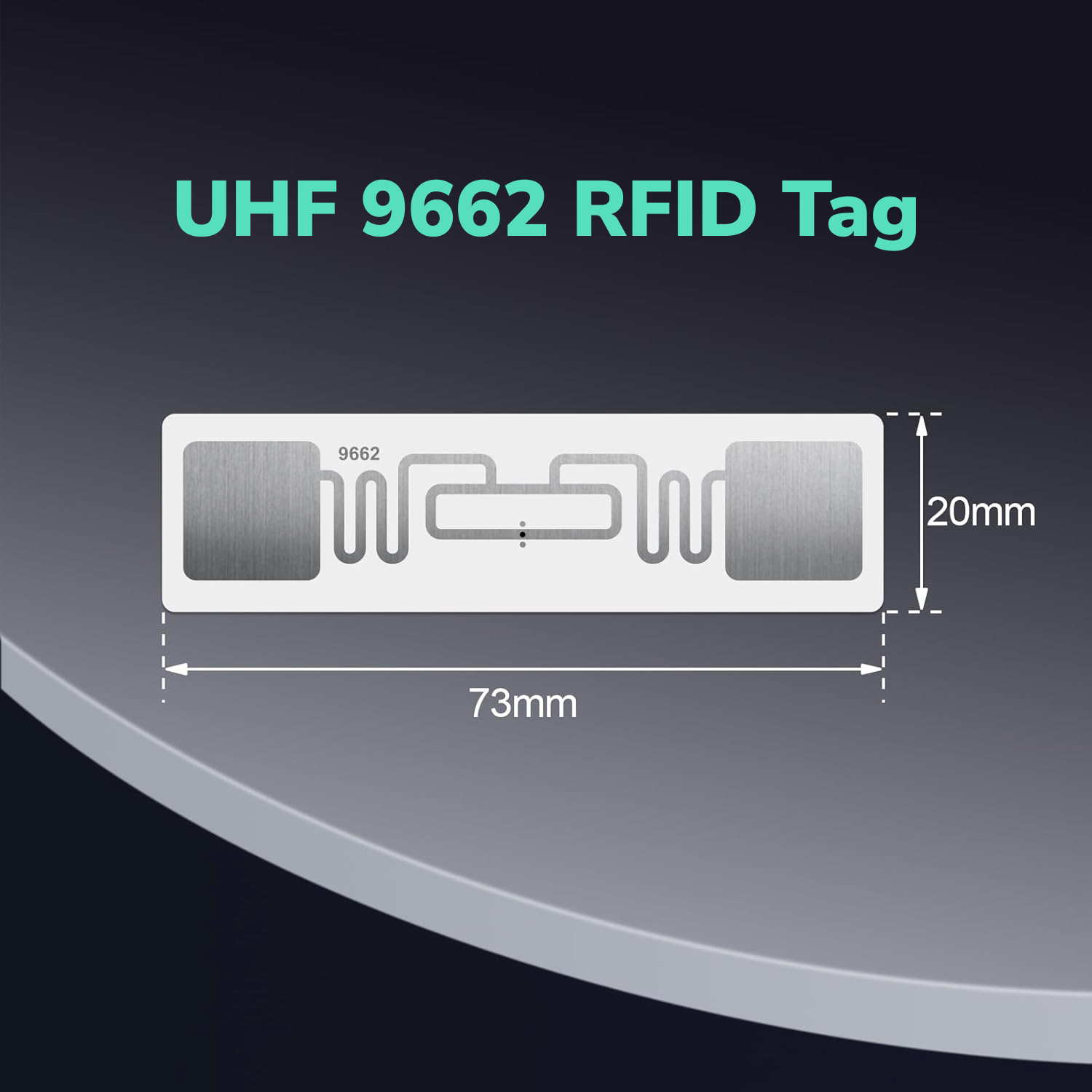

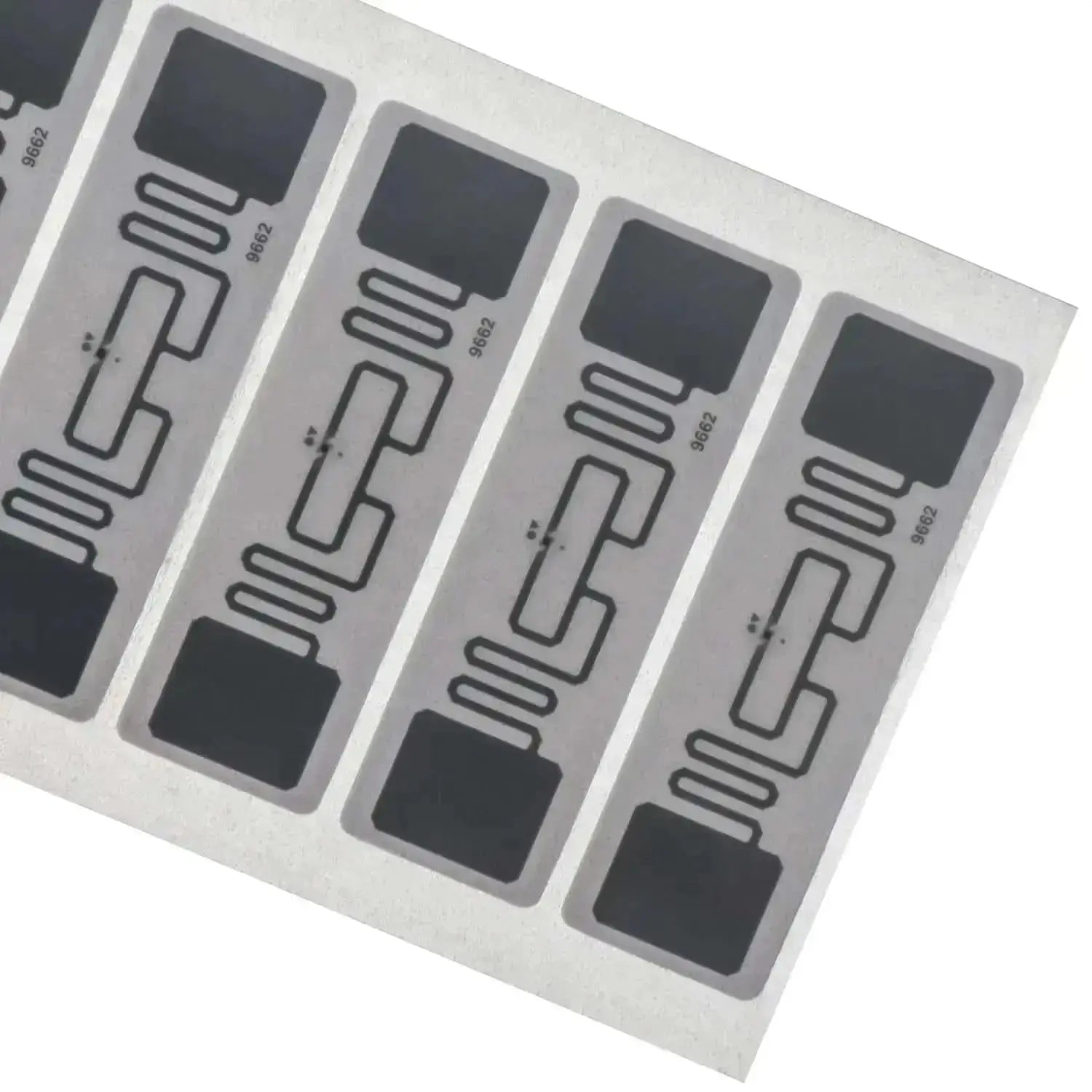

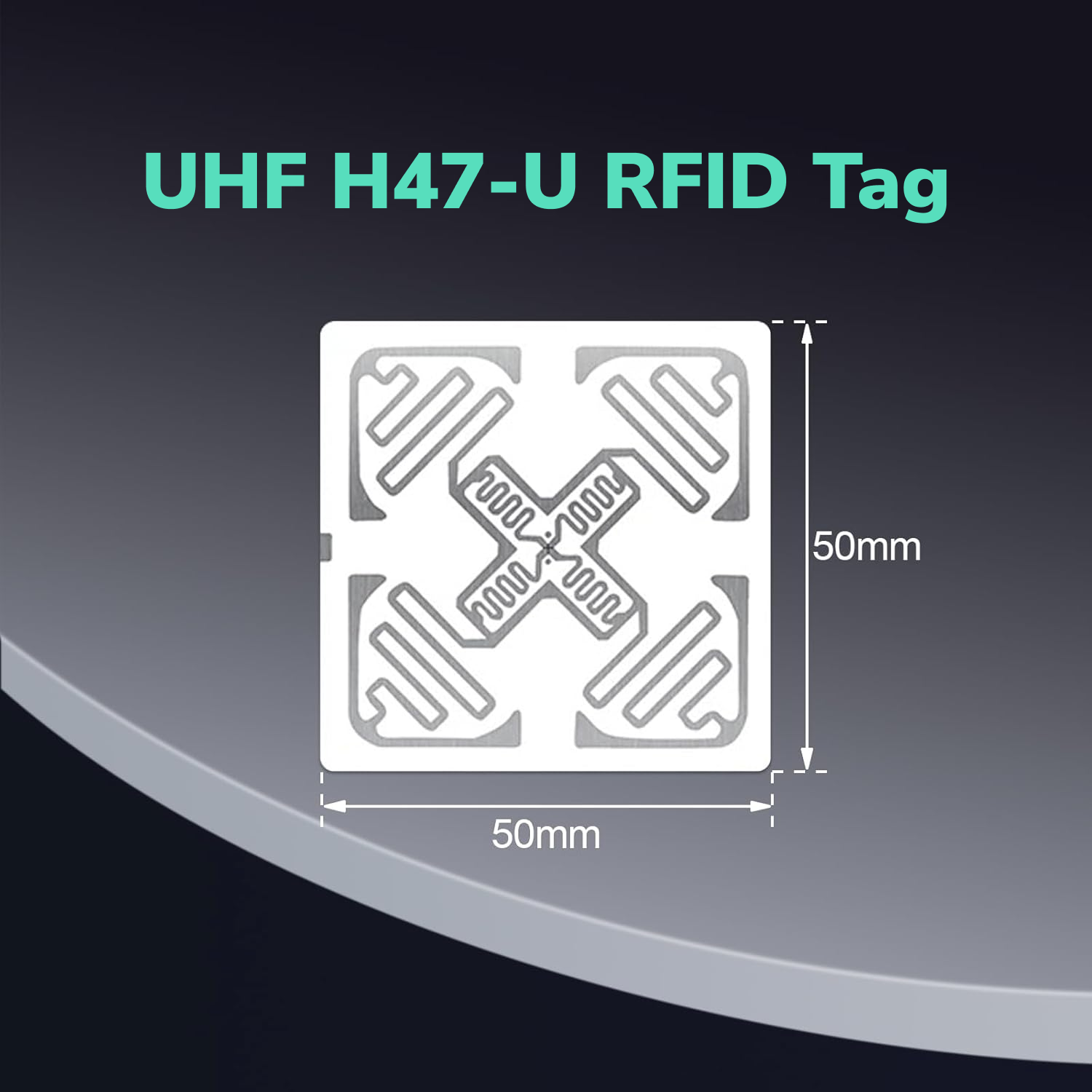

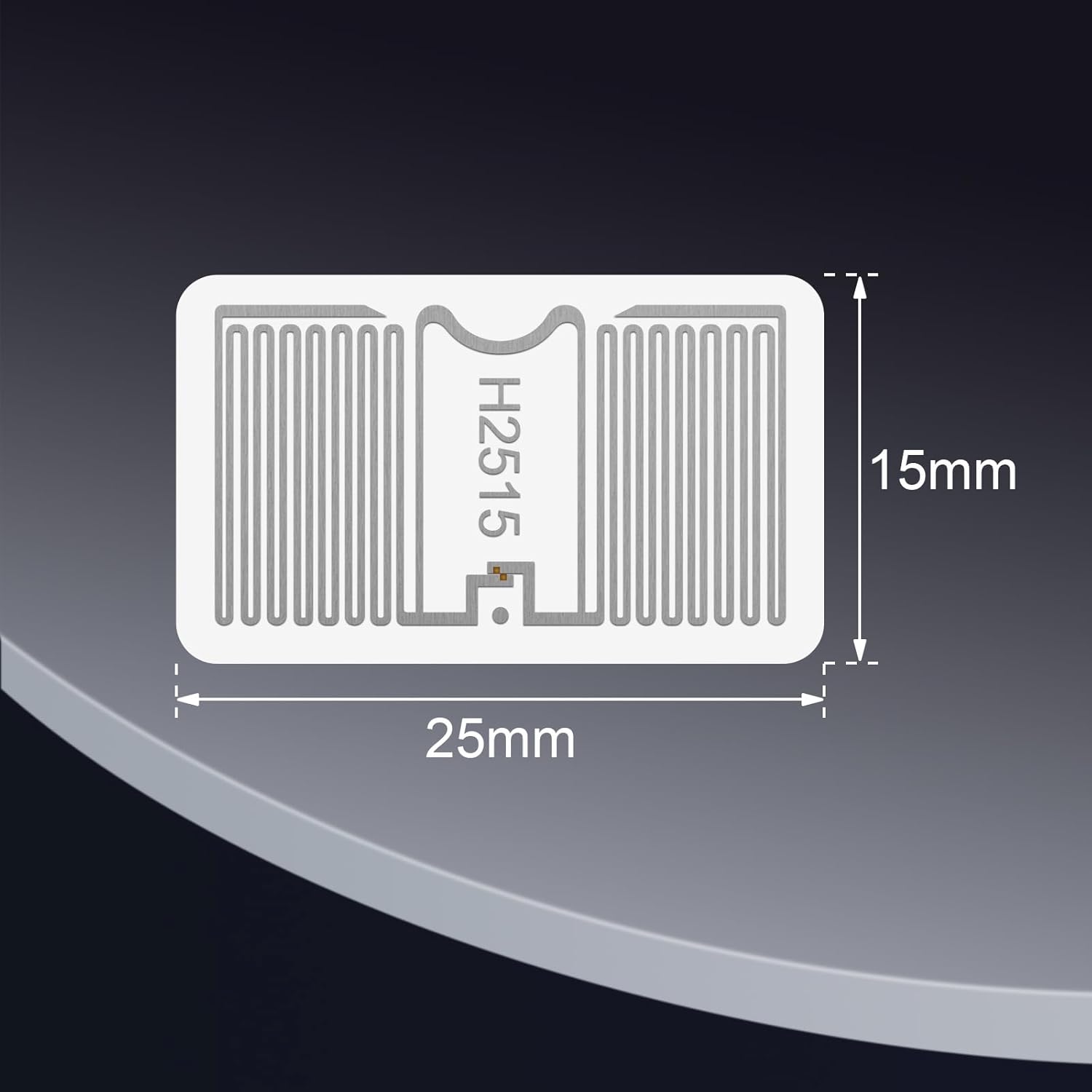

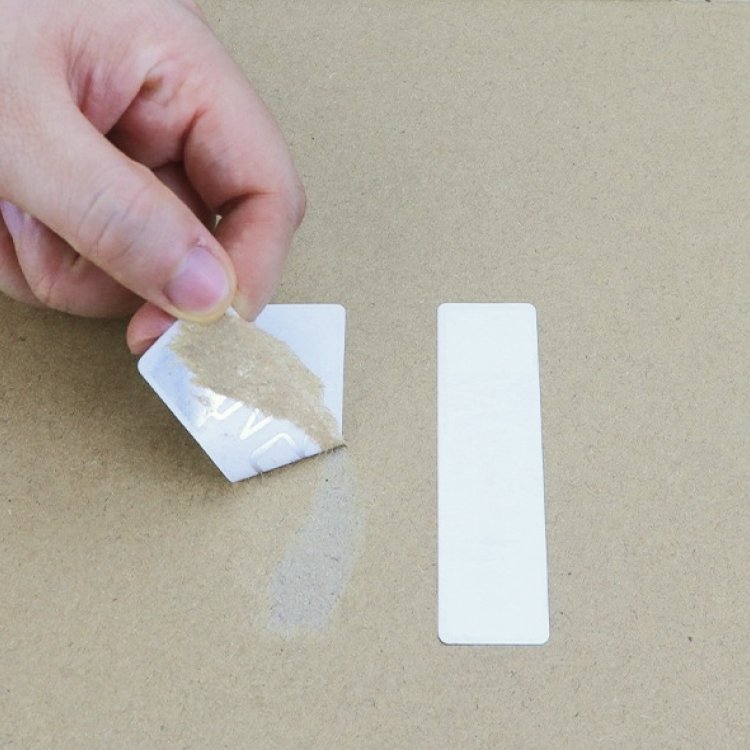

- Tags: These microchip-based devices encode unique identifiers and attach to assets. In a recent study by Walmart, adopting RFID tags led to a 16% increase in inventory accuracy and a 10% reduction in out-of-stock instances across stores.

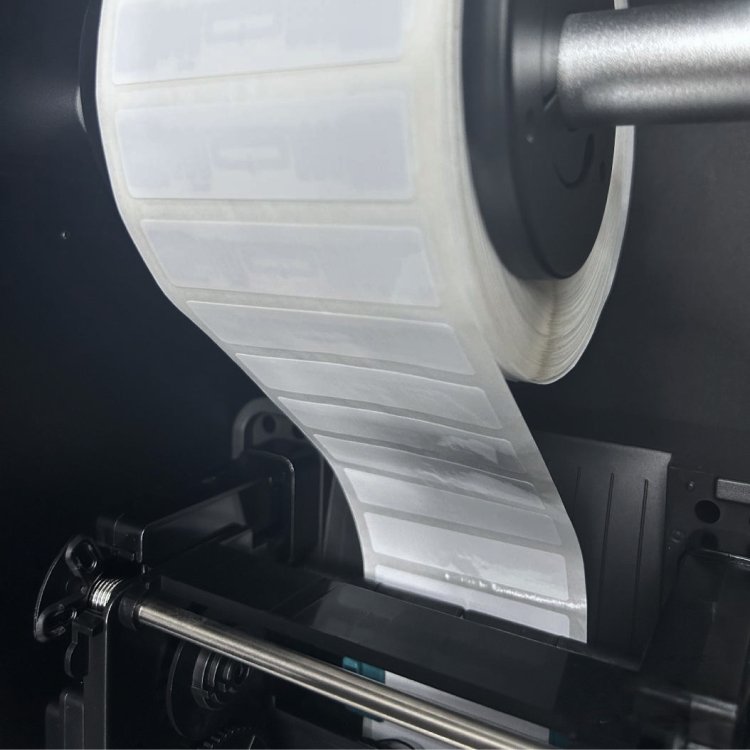

- Readers: Devices capturing data from tags. Amazon's utilization of RFID readers in their fulfillment centers resulted in a 25% decrease in order processing time and a 30% increase in overall efficiency, as reported in their annual sustainability report.

- Databases: Central repositories storing information collected by readers. According to a study by the RFID Lab at Auburn University, businesses leveraging RFID databases experienced a 43% reduction in excess inventory and a 32% decrease in supply chain-related costs within two years of implementation.

Active vs. Passive RFID Tags

- Active Tags: These powered tags emit signals independently. The Port of Singapore integrated active RFID tags in its container tracking system, achieving a 40% reduction in container processing time and a 25% increase in overall port productivity.

- Passive Tags: Drawing power from reader signals. The Metropolitan Museum of Art in New York City implemented passive RFID tags for artifact tracking, leading to a 20% reduction in misplaced items and a 30% increase in inventory accuracy, as reported by museum officials.

You can find out more details on the difference between active and passive rfid tags here.

Building an RFID Tracking System

- Tag Selection: Tailoring tags to specific needs. In a logistics case study, choosing RFID tags suitable for varying environmental conditions led to a 35% decrease in tag failure rates.

- Reader Deployment: Strategic placement optimizing coverage. A manufacturing facility realized a 30% increase in asset visibility by repositioning RFID readers along critical production lines.

- System Integration: Merging RFID with existing infrastructure. A healthcare institution integrated RFID tracking, resulting in a 50% reduction in misplaced medical equipment within hospital premises.

RFID asset tracking systems are not just a technological advancement; they are an operational game-changer. Their precision and efficiency not only streamline asset management but also offer tangible improvements across diverse industries. By integrating specific examples, case studies, and quantifiable data, this expanded section offers a deeper understanding of how RFID systems operate and their impactful contributions to asset tracking across various sectors.

Where to buy UHF RFID tracking stickers?

The availability of UHF RFID tracking stickers can vary based on your specific needs and location. Here are a few general avenues where you might find UHF RFID tracking stickers:

1. Online Retailers and Marketplaces:

Platforms like Amazon, Alibaba, or specialized RFID technology retailers often offer a range of UHF RFID tracking stickers. Check for reputable sellers and ensure the product meets your required specifications before making a purchase.

2. RFID Technology Suppliers:

Directly sourcing from RFID technology suppliers or manufacturers specializing in RFID solutions might provide a broader range of options. Companies like HID Global, Avery Dennison, or Impinj could offer UHF RFID tracking stickers among their products.

3. Local Electronics or Technology Stores:

Some local electronics or technology stores may carry RFID products. Contacting them directly or visiting their stores could help identify whether they stock UHF RFID tracking stickers.

4. Industry-Specific Suppliers:

Depending on your industry, specialized suppliers catering to sectors like logistics, healthcare, or manufacturing may offer UHF RFID tracking stickers tailored to specific needs.

5. Direct from Manufacturers:

Approaching manufacturers of UHF RFID tracking stickers directly might provide customizable options or bulk purchasing discounts. Companies like Alien Technology or Smartrac produce RFID tags and stickers.

6. Online Forums or Industry Communities:

Engaging in RFID-related forums, communities, or industry-specific groups could offer recommendations or insights on where to purchase UHF RFID tracking stickers based on experiences and user reviews.

When purchasing UHF RFID tracking stickers, ensure they meet your requirements in terms of frequency, compatibility with your RFID system, read range, and environmental suitability for the intended use. Always verify the credibility of the supplier and the quality of the products before making a purchase.

RFID for Inventory Tracking

RFID inventory tracking relies on RFID tags attached to items and RFID readers strategically placed throughout the inventory area. As tagged items pass within the read range of RFID readers, they emit radio waves, which the readers capture, interpreting the unique identifier embedded within the tags. This information is then transmitted to a central database, updating inventory records in real-time.

RFID Inventory Tags:

RFID inventory tags come in various forms - passive or active - each with distinct functionalities:

Passive RFID Tags:

Functionality: These tags rely on the energy emitted by RFID readers to transmit data.

Use Case: Ideal for shorter read ranges and cost-effective solutions.

Technical Aspects: Passive tags consist of an antenna and microchip. When within the reader's range, the reader's electromagnetic field energizes the tag's antenna, enabling the chip to transmit its data back to the reader.

Active RFID Inventory Tags:

Functionality: Equipped with an internal power source, active tags autonomously emit signals.

Use Case: Suitable for long-range tracking or monitoring items in motion.

Technical Aspects: Active tags contain a power source (usually a battery) that enables continuous signal transmission. This allows for greater read ranges and the ability to continuously transmit data, making them suitable for tracking items across larger areas or in dynamic environments.

Deploying the right type of RFID inventory tags depends on factors like read range, environmental conditions, and cost-effectiveness, ultimately optimizing inventory management, and ensuring accurate and efficient tracking processes.

RFID GPS location tracking combines the capabilities of RFID technology with Global Positioning System (GPS) technology, offering a comprehensive solution for precise asset location and tracking.

You can find out more details on the difference between active and passive rfid tags here.

Implementing RFID Inventory Tags

RFID technology offers a paradigm shift in inventory management, enabling:

Enhanced Tracking Capabilities

RFID ensures real-time and accurate tracking of inventory items, providing insights into stock levels, movements, and locations. This minimizes errors and enhances overall inventory accuracy.

Inventory Visibility and Efficiency

By utilizing RFID inventory tags, businesses gain instant visibility into their stock, facilitating quicker stocktaking, reducing stockouts, and expediting replenishment processes, all contributing to operational efficiency.

Streamlined Workflow Processes

Integration of RFID technology streamlines workflows by automating data collection and tracking, freeing up human resources for more strategic tasks ultimately boosting productivity.

Scalability and Adaptability

RFID solutions are highly scalable, and adaptable to various industries and inventory types. Whether managing a small-scale inventory or a vast warehouse, RFID systems can be tailored to specific requirements.

Cost Savings and Return on Investment (ROI)

While initial implementation costs exist, the long-term benefits of RFID often outweigh these expenses. Improved accuracy, reduced labor costs, and minimized errors contribute significantly to ROI over time.

Using RFID for inventory tracking involves deploying RFID technology alongside specialized inventory tags to streamline and optimize the inventory management process.

How RFID GPS Tracking Works

- RFID Technology: RFID tags are affixed to assets and contain unique identifiers. As these tagged assets move within the vicinity of RFID readers, they emit radio signals, carrying their identification information.

- Integration with GPS: RFID readers equipped with GPS technology capture the RFID signals emitted by the tags. Alongside this, GPS receivers determine the geographic coordinates of the RFID readers' locations.

- Data Fusion: By amalgamating RFID tag data with GPS coordinates, the system accurately pinpoints the location of the assets in real-time. This fusion enables both item-level identification and precise location mapping.

GPS Tracking Stickers in RFID GPS Systems

GPS tracking stickers, incorporating both GPS receivers and RFID tags, are attached to assets. These stickers have built-in GPS capabilities to acquire location data, along with RFID components enabling unique identification.

Technical Aspects:

GPS Functionality: GPS tracking stickers use satellite signals to determine their location.

RFID Components: These stickers also contain RFID elements, allowing for unique identification and data transmission when within the range of RFID readers.

This integration empowers businesses with a comprehensive tracking solution, providing not just item-level identification through RFID but also precise geographic positioning through GPS technology. The amalgamation of these technologies enhances asset tracking accuracy across diverse environments and use cases.

Conclusion

RFID technology revolutionizes asset and inventory management, providing real-time data, enhanced accuracy, and streamlined operations across industries. Its intricate system, combining tags, readers, and databases, orchestrates seamless tracking capabilities. RFID tags emit unique signals captured by readers, translating into actionable data stored in databases. This symbiotic relationship empowers businesses to monitor, locate, and manage assets with unparalleled precision and speed.

Beyond technological prowess, RFID's transformative impact spans diverse sectors, from optimizing supply chains to enhancing healthcare. Its adaptability and efficiency intertwine threads of accuracy, efficiency, and innovation, shaping a future of enhanced productivity. As technology evolves, RFID's story in asset tracking promises greater advancements and transformative possibilities.